General principles

Application areas using SiTek PSD include

- Non-contact distance measurement system (triangulation)

- Alignment and surface level measurement

- Position and motion measurement system

- Optical spectrum analizer

- Three-dimensional machine vision (contour mapping)

- Angle measurement system

Non-contact distance measurement system (triangulation)

The system uses the technique of optical triangulation.

By projecting a laser or a LED on a surface and then measuring the scattered light position through a lens system and a PSD, it is possible to determine the distance to the object. The distance can be measured with extreme precision and at high speed thanks to the outstanding linearity and resolution as well as the short rise time of the PSD. The ability of the PSD to operate with various light intensities makes the measurement system insensitive to ambient light.

|

Industrial applications of this technique include: - Height and thickness control in manufacturing processes - Guiding robots during the welding of thin metal sheets - Performing quality checks of car bodies and engine parts - Examination of road conditions at a speed up to 90 km/h |

Alignment and surface level measurement

A narrow and low divergent laser beam forms a straight line between two points. This laser beam can be used to align or level assembly tracks, conveyor lines, architectural subframes etc. A PSD is used to obtain a high accuracy displacement reading of the measured object relative to the laser beam. The PSD is fixed on the object and the laser strikes the PSD's active area. Movements of the object can than be determined with high speed and high accuracy.

|

This system is used for: - Measurement of straightness and flatness, squareness of face plates, beams, machine beds, machine tools - Measurement and adjustment of bearing journal, and propeller shafts - Frame straightening and alignment - Alignment of machine and machine components - Adjustment for parallelism of roller motors - Centering and positioning of work pieces in drilling machines, milling machines and lathes - Measurement of flatness of floors and concrete foundations |

Position and motion measurement system

This system uses high-precision two-dimensional PSD from SiTek. The PSD is mounted in a PSD camera. (PSD instead of film in the focal plane). On the object that is going to be examined, LED light sources are attached. These LEDís are turned on in sequence. As the LED is turned on, the camera determines the position of that LED.

To obtain a three-dimensional measurement system, two or more cameras are needed. A computer calculates the 3D points, their velocity, acceleration and displacement. This system works with high precision and without moving parts. Motion analyses can be carried out in real time.

|

This system is used for: - Anatomical studies, gait analysis, ergonomic studies, sports medicine - Car crash, impact analysis - Robot check, dynamic measurement of industrial robots |

Optical spectrum analyzer

With the optical spectrum analyzer incorporating this novel design, it is possible to make real time spectral analysis of light sources in the range of 200 - 1100 nm. It is a very simple system with a minimum of moving parts. The optical system consists of a collimator, a prism and a focusing lens. The light source, chopped by a mechanical chopper and divided into its wavelength components of the prism, is projected on the PSD. A very narrow slit is placed in front of the PSD. As the slit is moved along the PSD surface, the PSD will indicate the different spectral lines.

To determine the exact position of the slit, a light source of different modulation frequency than the measured light is applied in front of the slit. The measured spectral light signal and the position signal are divided by the electrical circuits following the detector.

Also for colour measurement

A simplified configuration of this spectrum analyzer can be used to measure the wavelength (or colour) of a monochromatic light source, such as an LED or a Laser Diode. For instance, this can be useful, in the quality control of the above products when determining the peak wavelength.

In this simplified configuration, the slit and the mechanical chopper is eliminated. The light source, when passing through the prism, will deflect onto a certain position in the PSD. The position is related to the peak wavelength of the light source.

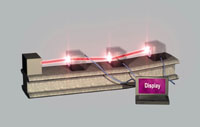

Three-dimensional machine vision (contour mapping)

This system uses the technique of optical triangulation for distance measurement and is combined with a scanning laser beam. While the laser beam scans the object a large number of distance measurements are taken. Also the scanning angle of the laser beam is measured with another PSD. With these measurements of the angle of the laser beam and the distance to the object, the electronic system is able to calculate a height profile or contour. The system is non-contact and is capable of measuring with high accuracy under extreme environment conditions.

|

The system was primarily developed to guide a welding robot, but other applications are: - Robotic guidance and inspection - Applying sealants or adhesives - Contour mapping |

Angle measurement system

This system takes advantage of the SiTek circular PSD, with which it is possible to make non-contact angle measurements. A narrow light beam (laser or LED) is projected on a mirror on the measured object (rotating shaft). The mirror deflects the beam according to the angle of the shaft. The light beam is projected on the PSD which detects the light spot position. The system can work with very high speed.

« home