The PSD (Position Sensing Detector) is an opto-electronic device which converts an incident light spot into continuous position data. It provides outstanding resolution, fast response and excellent linearity, for a wide range of light intensities and simple operating circuits.

PSDs for every need

At SiTek we are able to meet the requirements for any type of high quality application; for existing measurement tasks as well as for new inventions in their development phase. We offer four different product groups: a standard series of 1-dimensional and 2-dimensional PSDs, the NT-series, and customised design PSDs.

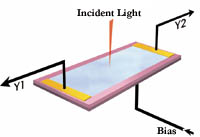

1-dimensional PSD

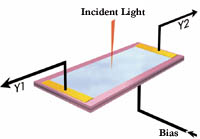

The one-dimensional PSD is able to detect a light spot moving over its surface in one dimension (a straight line). It has three terminals, one on the back side and two on the front side. The photoelectric current generated by the incident light flows through the device and can be seen as an input bias current divided into two output currents, Y1 and Y2 . The relationship between these two output currents gives the light spot position through the formula

where L is equal to the length of the PSD. With this equation the intensity of the incident light spot does not affect the calculation of the light spot position. Examples of use of 1-dimensional PSDs are height and thickness measurement, wheel alignment, profile measurements, inspection of manufactured parts etc.

Position =

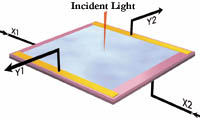

2-dimensional PSD

The two-dimensional PSD is able to detect a light spot moving over its surface in two dimensions. The duo-lateral PSD, which SiTek manufactures, has four terminals, two on the back side and two on the front side, where the terminals on the back side are placed perpendicular to the terminals on the front side. The photoelectric current generated by the incident light flows through the device and can be seen as two input currents, X1 and X2 , and two output currents, Y1 and Y2 . The relationship between the currents gives the light spot position through the formulas

where Ly and Lx is equal to the length of the PSD in the Y and X dimensions respectively. With these equations the intensity of the incident light spot does not affect the calculation of the light spot position. The separation of the two dimensions, unique to the duo-lateral PSD, ensures excellent linearity compared to other kinds of two-dimensional PSD.

Position y = Position x =

Examples of use of 2-dimensional PSDs are position and motion monitoring in car crash analysis, robot check or anatomical studies, measurement of straightness, flatness, parallelism etc.

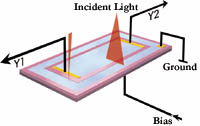

NT PSD

The presence of stray light from internal reflections in the measurement probe, from secondary reflections from the object (i.e. semi-transparent material), or from light scattered by smoke, dust etc. may cause problems. This is the major drawback in every light-based measurement technology. In 1995 SiTek introduced its patented solution with a new generation of PSDs which have an inherent stray light elimination. This means that you are now able to take full advantage of the PSDs high measurment speed and high resolution, even in applications where stray light has previously forced the use of other, inferior solutions.

The NT solution fits best for one-dimensional PSDs. Apart for the normal three terminals, it has an extra terminal on the front side. This extra terminal is connected to an extra active area on the PSD which will handle the disturbing stray light. By connecting this extra terminal to ground, the signal caused by the stray light will not interfere with the position signal. The position is calculated in exactly the same way as for the one-dimensional PSD by using the output currents Y1 and Y2.

Examples of use of NT PSDs are guiding robots during welding, measurement of the level of molten metal, inspection of semiconductor components etc.

ES PSD (Enhanced-Sensitivity PSD)

The ES series of PSDs has a built in amplification of the light-generated photocurrent. As a matter of fact the ES-PSD is a large phototransistor contrary to the standard PSDs, which is a large area photodiode.

The amplified photocurrent in the ES-PSD is divided in the same fashion as the standard components and thus the position signal is calculated in exactly the same way. Any standard PSD can be directly replaced by a corresponding ES component.

However, for a given light input the ES will give higher output currents and the connected electronics has to be designed to cope with this higher signal level.

Also, due to the larger internal capacitance in the ES component response speed will be somewhat lower.

The ES-PSD is mainly aimed for applications where low light intensities are used and where speed is not of primary concern.

Such applications can for example be measurements performed on low reflectivity substances such as for example rubber or applications where the used light source intensity has to be limited due to health concerns.

« home